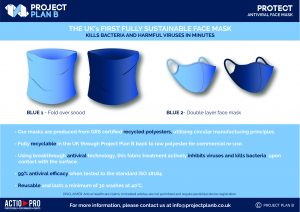

UK organisations PCIAW and Project Plan B have joined forces to swiftly bring an anti-viral, sustainable snood to market, aimed at protecting essential workers and commuters.

Plymouth company Project Plan B produce the face covering entirely in the UK, with a Leicester-based manufacturer. They are members of Milton Keynes based PCIAW (Professional Clothing Industry Association Worldwide) and immediately turned to the industry association once they were ready to bring the product to market.

Project Plan B knew that the issue that could arise from a snood would be the possible contamination of the fabric from hands, touching the fabric to put on, adjust, or remove the snood. Their response was to add a treatment to the fabric to stop the risk of infection through the hands.

Working with an internationally renowned fabric treatment company, Project Plan B have ensured their snoods are protected with anti-viral treatments necessary to defeat bacteria and viruses, including coronaviruses. The malleable nature of the snood also largely reduces the need to touch and adjust the product, decreasing the possibility of contracting the virus.

This innovative technology has been tested successfully against the virus that causes Covid-19. After treatment the fabric is resistant to harmful microbes and viruses.

Cyclical life span

Importantly once the snood has reached end of life, Project Plan B will take the snood back to recycle it and ensure a cyclical life span that doesn’t endanger the planet. Everything Project Plan B do is designed to be recycled.

Tim Cross, Director of Project Plan B, explained: “When the Coronavirus pandemic started, we immediately wanted to know how we could help. We didn’t want to disrupt existing supply chains that were equipping the NHS with medical masks, but focused our attention on the essential workers who are still potentially exposing themselves daily to virus. We were especially concerned that in this rush to supply, the environment was being ignored.

“We completely understand that during a time of crisis we have to act quickly to protect lives. However, it is surely incumbent upon us as designers and product developers to think about the products end of working life. At Project Plan B we believe you must design everything to be recycled at end of life so that you can use those fabrics, so rich in resources again and again. The textile world needs to think in a circular way and build in sustainability to their design. Our face covering is made from recycled polyester and can be recycled back into usable polyester at end of life, with built in circularity, to be used again and again.

“Disposable masks are adding to the industry wide problem of mass manufacture and waste.” The cost of the product will be considerably cheaper than other options available in the market, making it accessible for all people.

The snood offers everyone, especially commuters an easy to wear face covering that is practical and sustainable.

“Our motto here is protect others, protect the planet”, Tim continued. “The garment will be made from recycled plastic bottles and the treatment will last for at least 30 washes. We, of course, are concerned with the sustainable aspect of everything we do and wanted to make sure this garment would have the longevity and durability needed.”

PCIAW CEO and founder, Yvette Ashby added: “PCIAW is the first and only worldwide organization developed to represent the global companies of the professional clothing industry, we encompass the entire supply chain from buyers, suppliers, manufacturers. We are thrilled to provide our extensive knowledge and contacts to help members such as Project Plan B bring products to market. In the time of this pandemic, innovation in PPE (personal protective equipment) is more vital than ever and we hope other companies will follow Project Plan B’s lead in their affordable, sustainable product offering.”