Laser systems from Epilog turn T-shirts, jeans pockets and more quickly into individual and decorative pieces. The company cameo Franz Hagemann GmbH distributes the devices exclusively for Germany, Austria and the Benelux countries.

Rhinestone applications in an intrinsic design or over a large area? “This is only possible with a laser device – quick, at low cost and of high quality,” says Torsten Herbst, Managing Director of cameo Laser Franz Hagemann GmbH. For example, machines such as Epilog Zing or the newest laser development – the Epilog Fusion with a particularly large working field – are used for that.

Special branding effect

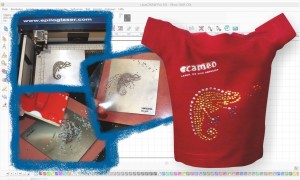

“Our machines are compatible with the very latest computers, also with Apple computers, which is a basic requisite for textile decoration with rhinestone,” says Herbst. Designs, letterings and emblems are created in different sizes at the computer and, with one touch of a button, the laser device brings them quickly onto the fabric.

On fleece, leather, softshell or velvet it creates an additional and special branding effect. These shade-in-shade patterns can additionally be finished with rhinestones. The positions and the sizes of the stones are also set up at the computer. The data are then delivered to the device by means of the design software LaserDraw, a development of cameo Laser, and within a short time the device cuts the corresponding plastic template with cleanly cut holes.

In the next step, the rhinestones are placed with a special brush within the template. The stones always fall with the smooth bottom side that has glue facing down, while the sparkling side is always facing up. Now a transparent film, the transfer film, is placed on top of the stones and the stones adhere to this film. It can now be removed from the template with all the stones on it and be placed on the fabric. The striking thing is that the rhinestone pattern matches exactly with the contour of the previously lasered area. The stones are then permanently fixed to the fabric with a heat press at about 1700C within 30 seconds. At the end, you remove the film and no stone will remain on it.

“This Wow effect can be achieved in only 10 minutes with the help of a laser. This enables the creation of very special unique pieces or series with low production costs. Once the template is created, it can be re-used,” explains Torsten Herbst. “This demonstrates that a laser is an incredibly versatile device that allows combining different techniques in a profitable way.”