Part 5: Readers’ questions

In a multi-part series of articles Holger Beck helps you to recognise potential problems and to develop solutions. Patent remedies are not available for every problem; however by understanding the backgrounds it is possible to deduce recommendations that help working more quickly, more cost-effectively and preventing complaints. In this fifth part he discusses questions that he has received from readers.

In a multi-part series of articles Holger Beck helps you to recognise potential problems and to develop solutions. Patent remedies are not available for every problem; however by understanding the backgrounds it is possible to deduce recommendations that help working more quickly, more cost-effectively and preventing complaints. In this fifth part he discusses questions that he has received from readers.

Transfer printing – by Holger Beck, www.seftextile.com/www.sef-france.com

Best knife for cutting reflex films

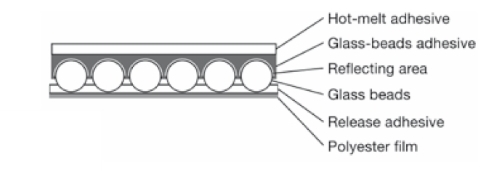

Reflex films usually have a thickness of 150 μ– 180μ and, contrary to flock films, practically the entire film must be cut through, due to the different production processes.

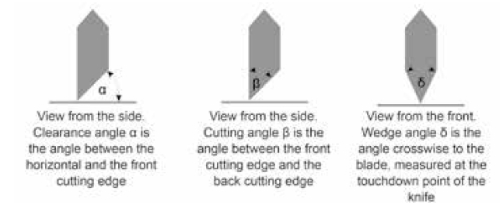

With reflex films, usually the glass beads are fixed first on a carrier. Then they are mirror coated on the rear and at the end, the glue and hot-melt glue are applied. So you have to cut about 160 μ, which is just the limit, where the use of a pointed knife (flock knife) still makes sense. However, if the film is quite elastic, you should rather use a 45° knife. More important than the cutting angle / clearance angle is the wedge angle for reflexive films . The bigger the wedge angle is, the longer the knife stays sharp, in spite of the glass beads.

Films with strong adherence

Films that have a strong adherence are not easier to cut because, contrary to popular belief, a strong back stickiness is not the same as a strong adherence. A strong adherence can also be achieved with few or no back stickiness at all. FlexCut Sweet for example is a flex film with a good adherence on the carrier but with no back stickiness at all.

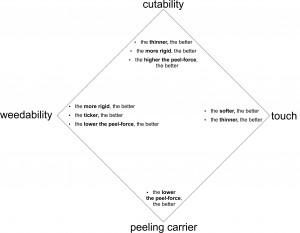

A good adherence is indeed good for cutting, because the stronger the adherence of a film, the easier it can be cut. However, in the following processing steps this can be a handicap, because the film will tend to tear apart during weeding and you will need more time for the weeding process.

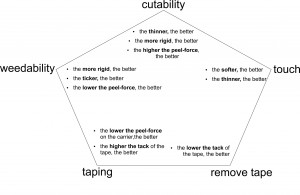

In order to prevent this, the film needs to be thick and tenacious, which has the disadvantage of an uncomfortable touch and feel. You have to find the correct balance between the competing goals of cuttability – weeding properties – releasing from the carrier – touch and feel.

Adherence of printable Flexfilms

Printable Flexfilms don’t have a stronger adherence. Also here, it becomes obvious that a high stickiness and a strong adherence are not the same. Most printable Flexfilms have no stickiness but adherence. And why is this adherence sometimes so weak that it becomes difficult to cut the films? With a higher adherence, it would not be possible to release the film from the carrier. You could use a tape with a stronger adherence, however, it would be difficult to tear off the tapes after the transfer and the fabric would possibly be distorted. Printable Flexfilms have, furthermore, an additional conflict area.

Press temperature with cover paper

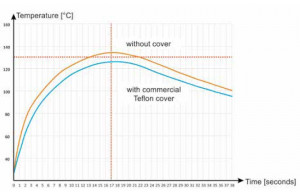

The necessary press temperature depends on the materials you will be using. A sheet of 80 gsm paper reduces the temperature at the hot melt-glue after 17 seconds at 165°C by 5°C. A commercial Teflon cover sheet of 250 gsm reduces the temperature under the same conditions by 10°C. Therefore this is the temperature difference that you should raise the setting temperature of your heat

press to in order to be on the safe side. If you use even thicker materials with higher insulation properties, such as rubber mats, you should raise the temperature even more.

Flock colours

The number of flock colours is limited because of the necessary size of a batch in the flocking machine. In order to run a flocking machine economically, you need 300 kg of flock fibres. With 100 g of flock per square metre, you will achieve about 3,000 m² of one colour. It is rather difficult to judge the period of time in which you can sell such a high quantity of flock film. This is why only the most popular colours are produced.

From: Stitch & Print International issue 3-2017