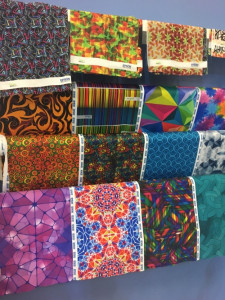

Sublimation is one of the most effective and fast ways to print fabrics. Many market segments have welcomed sublimation because of its low production costs and rapid results but I don’t think it is a good solution in the long term. In this article I would like to explain why I look at it that way.

Sublimation printing | by Maria José Leaño, www.papayad.com | Stitch & Print 4-2017

When starting up a business, business sustainability is crucial. It is important to be able to produce enough utilities in a short period of time to be able to survive and be successful for a lengthy period of time. Anticipating on how to react in different situations is another important matter. Printing as a business has proven to be difficult, and textile printing in particular. Not only do the images and colours have to be correct, they also have to last as long as the printed product is used. This is why ink and fabric development is so important. In textiles, inks have to be suitable for fabrics in order to satisfy the customer’s needs, to support friction, sweat and washing, and to not affect the user’s

health.

Sublimation addresses all of this with its simplicity and resistance. Even its biggest disadvantage, the fact that it hasto be printed on paper, became a plus when digital printing was developed. In those early stages, digital printers could not hold and transport fabric. Textiles, as we know, are flexible and will not stay still as paper to be printed correctly. That is why digital sublimation printing was developed before other types of textile printing. Today, machines have been developed that use disperse dies to print directly on fabric, but those are more expensive than the ones used for printing on paper. Other positive sides to sublimation are the relatively low initial investments and the fact that the polyester fabrics that are used are cheaper than natural fibres like cotton and silk.

Sublimation is easy. When printing indirectly, just print the paper and pass it through a heat press together with the fabric and there you go, the print is ready. There is no need for extra chemicals or fixation processes, the colours will blend with the synthetic fabric in a bond that even sunlight won’t be able to break and which will make the fabrics water and light resistant. When sublimation is done directly, the process is even simpler, as one prints directly onto the fabric and heat press. There’s no need for water, which is perhaps the biggest advantage of sublimation, compared to other printing processes using textile dyes.

The material used, polyester, is very strong and will last forever, making it a good choice for curtains and sofas in interior decoration. Being light resistant, this combination of sublimation and plastic is perfect for decorating and redecorating your home. It is also used for exteriors, replacing banner printing as a more friendly solution for the planet. It is also possible to use sublimation in accessories and publicity on objects that have a special polyester coating such as shoes, cups and tiles. Most sport garments are printed using sublimation, developed together with synthetic fabrics that are especially designed to sustain hard work and sweat. Cotton t-shirts won’t last in a football match or in La Tour de France.

So far, so good. Let’s see, however, what is behind all this.

Negative impact

At this point, I would like to give you some reasons why not to consider sublimation as the printing process to be used by your company and also suggest some ways how to reduce the impact that it makes. First of all, the fact that inks have to be printed on paper has a double negative effect. The first negative effect concerns the paper that is derived from trees, which are fundamental for our survival. I would suggest using recycled paper, or paper derived from by-products from other processes, such as sugar cane pulp. The second negative aspect concerns the ink, which contaminates the paper used in sublimation. The paper that is used cannot be used again. If you are thinking of buying a machine for direct sublimation printing, calculate with the expert if it would be possible to return the investment by saving on paper.

The ecological problems of sublimation printing are well known. Not only do the inks contaminate the air when they sublimate (and therefore the air that is inhaled by employees), but substrates that are used are a hazard too. The downstream and upstream cycles of the printed materials should be revised as well. Because sublimation can only be done on polyester, a product derived from petroleum, its extraction is considered negative for the environment. It is not biodegradable nor 100% recyclable. It has the same problems as plastic bottles, needing ears to transform into molecules that can be reabsorbed by nature. Moreover, its toxicity makes it bad for your skin. Collecting all used clothing for recycling is very difficult, especially if you live in a developing country.

Every time I criticise petroleum derived materials people argue that it is cheap, which is perhaps the best argument for a business to use, but is just a paradigm. What I am asking is why is petroleum cheap and for how long will it be cheap? I am not saying that plastics are bad. I do think that they are great materials. I am just wondering whether we aren’t overestimating their applications and underestimating their costs.

The low costs of petroleum derived materials are the result of the way petroleum is being priced around the world. We all now it is subsidised and I don’t want to go into any political or economic complexities. All I want to point out is that we ought to consider why it is so cheap. Maybe we are valuing it at a higher price than it deserves, higher than all the communities and ecosystems that are being destroyed to extract and degrade it. In the end, we are going to pay for all this, and we will only find out what the real costs are when it is too late and all reserves have run out. In my country, Colombia, this will happen within five years, after which we will be dependent on other economies to get the valuable stuff.

To avoid this happening, we can take many roads. First, other types of materials that do not derive from petroleum could be developed and used to replace part of the ones we know. Another suggestion would be developing ways to recover usable chemicals from plastic. All of this is not new, it is just not being done because it is expensive, another paradigm. The more I think about this, the more worried I get. I am sure that powerful people know this already, but they seem to have their reasons not to change it. Petroleum is expensive and so it should be. Its price should pay for research and the development of new and novel materials to replace it. The sooner, the better.

I know I was supposed to write about sublimation but, like many of us, I have become concerned about the planet. I hope that by not just focussing on one part of the story, but on the whole story, we can start to make a difference.