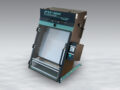

Polyprint S.A.officially launches a new addition to its family of DTG products: the PreTreater Pro.With this new machine businesses can now create loyal customers with stable, high-quality printing results.

Garment pre-treating is the foundation to achieving vibrant colors, sharp details and washability in DTG printing. With PreTreater Pro you get top-quality prints, consistency in repeated jobs and improved washability, while saving on liquid costs.

Consistent pre-treatment on every t-shirt

“Pretreater Pro is simple to use and has been created after careful consideration of customer needs. As a DTG printer manufacturer, since 2006, Polyprint has aimed to corner the market with innovative products that guide DTG businesses to their success. Pretreater Pro is designed to offer consistent pre-treatment every time, on every t-shirt.” said George Benglopoulos, CEO of Polyprint S.A.

“It’s time for DTG users to invest in their DTG business success with the right pre-treatment machine! Users are able to say goodbye to messy spray guns, inconsistent prints and dull colors. Businesses can now create loyal customers with stable, high-quality printing results! ” George adds.

“Repeatability and consistency are the key to successful production runs. Its auto re-circulation system ensures liquid homogeneity and prevents sedimentation, prolonging liquid life span. Additionally, an anti-corrosion Isolation Chamber (Box-in-a-Box design) ensures that mist is contained, protecting mechanical and electronical parts, thus prolonging the machines lifespan.” said Grigoris Gavrilidis, Head of Research & Development at Polyprint S.A.

Watch the machine in action:

Pretreater Pro features

- 41 x 60 cm true spray area (4 nozzles).

- 7” color touch screen with modern UI: enjoy intuitive messages and a helpful notification system, to avoid user errors.

- Precise Spray Area Selection: “Linear” (min. 10 x 1 cm) & “Grid” (min. 15 x 10 cm) edit modes, to only spray your desired area and save on liquids.

- Accurate Liquid Quantity selection per 1 ml. Spray the right liquid amount, avoiding costly experiments.

- Advanced Job & Liquid consumption calculators. Easily keep track of your production.

- Two liquid supported with automatic liquid switch and simple cleaning procedure.

- Auto Liquid Re-circulation System for both liquids. Gain liquid homogeneity, prevent sedimentation and ensure a consistent spraying pattern on every t-shirt.

- Distinctive anti-corrosion Isolation Chamber (Box-in-a-Box design). Minimize rust and prolong your machine’s lifespan.

- “Barcode Ready”. “Scan-to-spray” automation feature (stores spray area and liquid quantity).

- Easy access Tank Storage Compartment. 4 x 5 Lt commercial replaceable tanks (2x pretreat, 1x cleaner, 1x waste), to avoid messy situations during refills and enjoy a clean workspace.