After the success of the direct to garment printers GTXpro and GTXpro BULK introduced last year 2020, Brother are pleased to announce that the GTX family is getting even bigger.

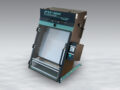

For mass production, you need perfect reliable tools and working equipment. With the latest member of the Brother family, the GTX 600 Brother is offering you this. With this new bulk machine, Brother were able to create a machine that is setting new standards and that is easy to operate.

Built for industrial-level performance

For your mass production business, you need equipment that you can rely on 100%, that can meet the dual challenges of high-quality design reproduction and industrial level activity. That is why Brother have been working closely with major producers to meet the high standards of mass production.

To keep the ink in a print ready state, the GTX600 has ink recirculation in four key areas. Brother developed 16 ink channels jetting from staggered, industrial print heads with internal cooling fans, for continuous print operation. Also, the ink is constantly filtered and degassed to guarantee you the best possible print quality up to 1200 dpi. The built-in humidifier ensures that the machine has always perfect working conditions, even in difficult environments and big production halls.

Engineered for leading performance

A machine should not only function perfectly but also be able to adapt to your business needs. The GTX600 can be used with different platens for endless creative possibilities, the platens can be changed quickly to save important time and their height is auto selectable which makes them adapted for any material that can possibly be printed on.

With this new DTG printer Brother have developed their technologies further. The printing speed has been increased and also the industrial maintenance station got upgraded to enable continuous and fast print operations. The auto cleaning frequency is much less than any printer before, which increases the real print productivity drastically.

At your side for a better future

As sustainability is an important issue Brother is offering solutions that limit the environmental impact and therefore create a better tomorrow for everyone. With their wet capping and inside ink print head circulating technology, ink waste gets reduced. Also for the GTX600 the inks are available in 9 liter and new 18 liter tanks, to help reduce packaging waste.

The innobella textile inks are water based, GOTS6 approved and Oekotex passport certified and therefore eco-friendly. Furthermore, the new DTG printer has a built-in mist filter, which ensures a secure working environment for the operator.

With the GTX600 Brother engineered a new mass production machine which also helps to reduce the pollution of the environment. They credit all this to more than 15 years of experience in garment printing. In close exchange with customers and experts Brother are constantly improving and innovating the machines and adapting and advancing them to the wishes and needs for their business. So that they continue to innovate, creatively produce the best solutions for the market and work together for a better tomorrow.