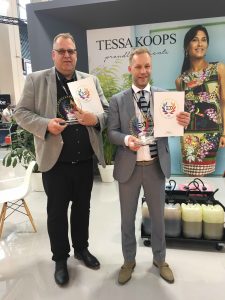

Mimaki celebrated winning two awards at the European Digital Press Association (EDP) Annual Awards ceremony, held at FESPA 2019 in May. Mimaki’s Tiger-1800B MkII was the champion of the day, earning its first award in the category of ‘textile printer roll-to-roll more than 100 square meter per jour’, and the second for its Rimslow TR Series complete solution, in the category of ‘pre- and postpress-treatment solutions’.

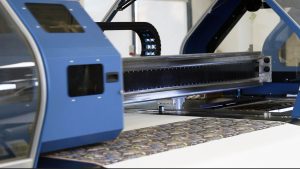

As part of the Tiger Pro Series, the Tiger-1800B MkII is a high-volume textile printer for direct printing or paper transfer with a print speed of up to 385 m²/hour. This versatility and speed paired with the printer’s ability to print at up to 1200 x 1200 dpi, enables users to produce extremely high-quality products without the need to compromise on production and throughput. Capable of handling all kinds of fabrics and papers, the printer can be used for a wide range of applications including tapestries, interior decoration and fashion & apparel.

Other important features of the Mimaki Tiger-1800B MkII include MAPS (Mimaki Advanced Pass System) and NRS (Nozzle Recovery System). MAPS prevents banding and colour-shifting during the printing process by spreading the edge of each pass to create a gradient. This feature alongside NRS, which enables the printer to replace damaged nozzles with operating nozzles without stopping production, enhances the printer’s performance and boosts productivity and quality for the user.

“We’re delighted that our Tiger-1800B MkII came first in two categories during such a prestigious awards ceremony,” says Bert Benckhuysen, Product Manager for Mimaki Europe. “To be recognised for the fact that we listen closely to the needs of the market and constantly work to improve our products for customers, affirms our position as a strong force within digital textile printing.”

Allowing textile printers to take full control of their workflow, the Tiger 1800B MkII and the TR Series is a complete solution for coating, printing, steaming and washing machines. Rather than purchasing technology from different manufacturers to handle the four production processes, Mimaki ensures complete technology compatibility, for improved efficiencies and quality.

“The Mimaki TR Series is all about increasing productivity and cutting costs throughout the whole digital textile printing process. Providing an entire workflow solution instead of a stand-alone product, enables us to offer a much more stable and reliable production line. This enables increased uptime and allows our customers to focus on designing products that make them stand out in the crowd,” Benckhuysen concludes.

During the 13th EDP Awards contest, over 100 entries across five main categories were made, with 28 products announced as winners. Chosen based on numerous criteria including quality, value to user and environmental impact, the winners were selected by 20 leading trade publications within the digital printing industry, reaching over half a million readers across 25 European countries.