Vastex launched the new PTF-100 Powder-To-Film Coating System with integral D-100 Conveyor Dryer that increases production of DTF film. The Vastex EconoRed conveyor dryers are now equipped as standard with an adjustable exhaust for optimising the curing of printed textiles, DTF films and/or powdered adhesives, while cooling the skin of the enclosure and minimising wasted heat, it was announced by Mark Vasilantone, president.

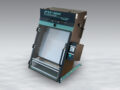

Mounted on a utility cart, the new mobile coating system allows an operator to apply a uniform layer of adhesive powder to a run of DTF graphics, and cure them uniformly in an infrared conveyor dryer from a single location. When not needed for DTF, the system can be rolled away.

The PTF-100 coating system (patent pending) features an angled steel casing and clear polycarbonate door with dust-tight seal for mess-free operation. Supplied as standard are two interchangeable cartridges, each of which can hold approximately 1.4 kg of adhesive powder, for quick and clean refills. The coating cabinet accommodates film up to 406 to 508 mm, and features an adjustable timer for repeatable results.

The compact D-100 dryer with 46 cm wide conveyor allows adjustment of temperature, belt speed and heater height to cure DTF film at high rates. An integral exhaust hood removes moisture and fumes for operator safety, which is especially critical in confined spaces typical of many DTF shops.

The heaters of all Vastex dryers carry a 15-year warranty, and feature closely spaced coils that provide high-density, medium-wavelength.

Adjustable dryer exhaust boots efficiency, safety

Vastex EconoRed conveyor dryers are now equipped as standard with an adjustable exhaust for optimising the curing of printed textiles, DTF films and/or powdered adhesives, while cooling the skin of the enclosure and minimising wasted heat.

Using a damper control knob, the user can adjust the volume of exhausted air from 100% to 10% to remove all fumes emitted in the heating chamber according to the size, weight, throughput and ink type of DTG and screen-printed garments, and/or the dwell time needed to cure powdered adhesives of DTF images or screen-printed transfers. Excess air flow unnecessary for exhausting of fumes is diverted and filtered to cool the double-wall skin of the heating chamber for worker safety.

“A wide range of variables determines the amount of exhaust air needed for any given run,” explains Vasilantone, “from high capacity evaporation and curing of water-based pretreatment and DTG-printed inks, to powdered DTF adhesive and screen-printed transfer films that off-gas significantly yet must be prevented from lifting off the conveyor belt due to high volumes of exhausted air.”

Together with digital control of heater temperatures in one-degree increments and variable belt speeds from .55 to 7 metres per minute, the adjustable exhaust allows operators to fine-tune all critical drying parameters on a job-to-job basis, while accommodating the differing exhaust requirements of systems having multiple heating chambers.

The adjustable exhaust is available on all EconoRed Series II and III high capacity dryers in belt widths of 76 cm, 137 cm, and 198 cm. All can be configured as new or retrofitted with additional heating chambers to double or triple curing capacity (belt speed) of screen printed plastisol inks, water-based inks and discharge, DTG pretreatment and printed images, and powdered adhesives of DTF substrates and screen-printed transfers.

Retrofit kits will be available for upgrading existing EconoRed dryers with adjustable exhausts.