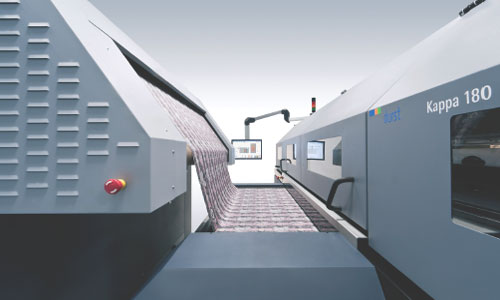

The previously announced Durst Kappa 180 will be launched at the ITMA 2011 in Barcelona. The digital printer for the textile industry is characterized by its fast printing speed (up to 600 m2/hr) and high printing quality (1056×600 dpi).

The Durst Kappa 180 is based on the Durst Quadro printhead technology and is a product of the Durst Development Center in Kufstein (Austria). This modification is called ‘QuadroZ’. The maximum print width is 195 centimeters. The high quality Kappa inks have been developed in the Durst Research Center in Lienz (Austria) and are water based.

The Durst Kappa 180 is based on the Durst Quadro printhead technology and is a product of the Durst Development Center in Kufstein (Austria). This modification is called ‘QuadroZ’. The maximum print width is 195 centimeters. The high quality Kappa inks have been developed in the Durst Research Center in Lienz (Austria) and are water based.

Consistent

The QuadroZ Arrays print eight colors in CMYK, orange, red, blue and gray, with no modulations or fluctuations in density. An important role has the ink filter system, based on osmosis, which eliminates small air bubbles in the ink and ensures consistent print quality.

Hannes Fischer, head of the Textile Development Center in Kufstein; “Durst Kappa 180 is a real alternative to flatbed screen printing on textiles. Because of its speed and print this digital printer offers new perspectives to the textile printing industry.”

Drying System

The Durst Kappa 180 textile printer has a fully automatic input and guidance system for textiles. The print sheet is cleaned with an integrated washing system. The drying unit consists of a hot air dryer powered by gas, steam or electricity.

Kappa ink

Especially for textile printing Durst has developed several Kappa ink systems: Kappa R (Reactive) for cotton and cotton mixtures with more than 60% cotton. Kappa D (Dispersion) inks for synthetic fabrics, polyester fabrics and mixtures with more than 50% polyester. Kappa A (Acid) inks are suitable for silk and silk-like mixtures.