Photo: DITF

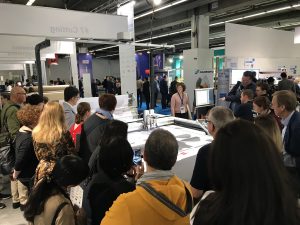

For the first time, at TV TecStyle Visions 2020, the German Institutes for Textile and Fibre Research (DITF), in cooperation with long-term partners from industry, will give a live demonstration of the Digital Textile Micro Factory in the L-Bank Forum (Hall 1). The complete production of a polo-shirt along the entire production chain, from the 3D design to the finished product, will be experienced.

The integrated showcase will highlight how technologies will change the individualisation and the production of batch size 1 in the area of workwear and printwear, important target markets of the fair. Production structures can thus be strengthened on location, nearshoring networks made more efficient, and new business models based on digital technologies created.

Virtual Shopwindow to the Micro Factory

The starting point for the Digital Textile Micro Factory (Stand 1B80) will be the “3D Design Area”, where creative designs will be produced using 3D simulation for the identification of orders for cutting and manufacture. The partners here are Assyst GmbH and the Hochschule Albstadt-Sigmaringen (university). In the virtual shop window, the product designs can then be viewed and individually composed on location with the support of the Technische Hochschule Köln (Cologne Technical University).

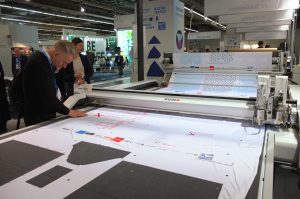

The multi-spectral colour communication by caddon printing & imaging GmbH will create the visual impression with exact measured values – pixel by pixel. In the next step, the designs created will be printed by means of sublimation printing by HP Deutschland GmbH on transfer paper. Thanks to the thermo-setting in the calender, carried out by system partner Multi-Plot, an optimum print result is ensured.

The following cutting is recognised with camera support and the help of integrated position markers, so that the material can then be cut to size fully automatically. This step will use cutting systems from Zünd Systemtechnik AG. Finally, the individual components in the manufacture will be finalised on JUKI sewing machines provided by Konrad Busche GmbH & Co. KG, and brought together live to complete the finished products. The material is sponsored by Schoeller Textil AG.

In this fashion line, the DITF will demonstrate creativity, customer interaction, virtuality and networked production. The fashion industry is becoming more virtual, physical samples can be visualised for customers in the context of on-demand processes. Integration in a micro factory highlights new opportunities of digitalisation and direct customer involvement. New approaches combine the data from the 3D clothing simulation directly with virtual and augmented reality (VR/AR), and integrate the data in the digital textile printing, cutting, colour management, down to manufacture. The micro factory provides opportunities for new business models, flexible and local production processes with small order quantities, as well as a quick route to tailor-made clothing that also takes into account current trends and customer requirements.

Guided tours through the Micro Factory will take place every day of the trade fair at 11.00, 13.00 and 15.00.