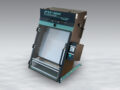

During Kornit Fashion Week Tel Aviv 2022 Kornit Digital Ltd. (NASDAQ: KRNT) introduced the Kornit Atlas MAX Poly system, a direct-to-garment (DTG) solution delivering high-quality digital decoration for vibrant, colorful design on polyester and poly-blended apparel.

The new Atlas MAX Poly capitalizes on the demand for fashionable, unique sportswear and apparel. As the industry emerges from a post-pandemic environment in which athletic and leisurewear became mainstream, there is increasing demand for apparel combining polyester and poly-blends with vivid designs across a range of colors. The new DTG printer can transform the multi-billion-dollar professional and recreational sports apparel and team wear markets, limited today by limitations in mass customization of polyester.

“Kornit Atlas MAX Poly is a game-changer,” said Omer Kulka, Chief Marketing Officer at Kornit Digital. “As fashion and sports apparel merge, there’s new opportunity for innovative fashion on polyester, currently the fastest-growing textile vertical. For the first time, recreational sportswear, promotional, and sports brands can embrace vibrant and colorful design with Kornit’s proven MAX technology, setting superior quality standards for on-demand production previously not possible.”

Endless designs and creativity

Unveiled during Kornit Fashion Week Tel Aviv 2022, Atlas MAX Poly incorporates Kornit’s field-proven MAX technology for high-quality premium decoration, process automation, and smart autonomous quality control. With Kornit’s XDi decorative applications, the printer enables endless designs and creativity on polyester, and empowers new styles for multiple effects and unlimited combinations such as emulating threadless embroidery, high-density vinyl, screen transfer emulations, and 3D effects.

The solution is compatible with mesh and plain fabrics, including brushed polyester, while maintaining durability and breathability. It brings the highest throughput for on-demand polyester decoration, reducing total cost of ownership to drive profitability. Customers gain competitive advantage via Pantone color-matching and a wide color gamut including neon colors for bright and vibrant impressions, using single-step mechanisms minimizing production footprints while maximizing versatility.

Beyond high quality, graphics, color, and application variety, the DTG printer offers efficient, reliable, profitable end-to-end polyester production via Kornit’s ActiveLoad automated garment-loading and pallet adjustment for repeatable, high-quality output with minimal errors reducing time and waste, eliminating operator ramp-up and boosting throughput up to 20%.

The printer seamless integrates with KornitX Global Fulfillment Network, enabling a pixel-to-parcel-to-doorstep experience. This unleashes untapped demand for polyester short-run production, personalization, and disruptive direct-to-fan and direct-to-recreational business models. There is also integration with KornitX’s workflow ecosystem and Kornit Konnect dashboard, optimizing process visibility and control, adding data-driven insights for production floor efficiencies.

The new Atlas MAX Poly is successfully deployed across four global beta customer sites with expected availability in quarter two 2022.