At Viscom 2016, cameo Laser will highlight the essence of Epilog lasers. Different application possibilities of the Epilog devices will be demonstrated.

Large processing field

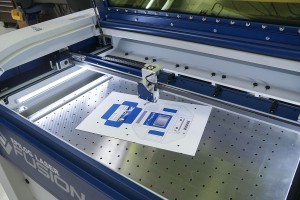

The Epilog Fusion lasers, which cameo Laser Franz Hagemann GmbH distributes exclusively in Germany, Austria and the Benelux countries, are important instruments in the production of advertisement technology and illuminated advertisements. These lasers include devices with a large processing field of 1016 mm × 710 mm for large products, such as displays or letters for outdoor advertisements, that can be produced simply.

Unprecedented speed of e-View

The Fusion lasers are equipped with the camera system, e-View, which will be presented at Viscom. This system consists of three cameras, one at the laser head and two within the housing of the laser, which capture the entire processing area. With these cameras the print and the cut are combined with the highest precision and at an unprecedented speed. For cutting out applications and letterings for different areas, it’s no longer necessary to align the material manually on the laser. The e-View camera system captures and reads the printed registration marks in no time at all. Michael Ebel, Sales Director at the cameo Kompetenz-Zentrum West, elaborates, “The data are then compared to the positions of the original file, and any deviation will be adjusted immediately. This allows streamlining the processes and speeding up the production time.”

Super-fine laser beam

Michael Ebel continues to explain, “The Epilog laser devices are currently the only systems on the market that are compatible with Apple computers. With their super-fine laser beam they can, furthermore, cut acrylic with crystal-clear polished edges, which shortens the processes in the illuminated-advertisement industry. With the laser you can apply a picture or a lettering by ablating the mirror layer and making the area transparent. A colour-changing light source placed behind makes such a mirror an absolute eye-catcher with a high attention value. For this finishing process, the Fusion is the first choice. Even large-format designs can be done in one single process.”