Konica Minolta will unveil two new inkjet textile printers at ITMA 2011. The Nassenger PRO 1000 for significantly high-volume production and the Nassenger PRO 60 for small production. The two models offer a total solutions to help users manage and implement the entire production process, from small-run production to full-scale manufacturing operations, solely by inkjet textile printing.

In recent years in the textile market an increasingly widespread attention has been drawn to on-demand production by inkjet textile printing systems, as it enables print works for a variety of printing in small lots, reduces excessive inventory in the distribution pipeline and meet the needs for short-run production of highly-demanded products of the moment, prompting a shift from conventional screen textile printing. Reflecting the expansion of digital textile printing market in its growth stage, Konica Minolta is showcasing the Nassenger PRO 1000 and Nassenger PRO 60 at ITMA 2011.

Enhanced functions

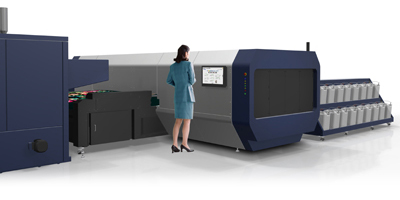

The Nassenger PRO 1000 features a number of enhanced functions for high-volume, full-scale production: With 1,000m2 per hour a fast print speed for scan-printing inkjetprinters, newly-developed high-density water-based printheads, a 40L ink tank for each of the nine colors and newly developed nozzle sensors and floating-fabric sensors.

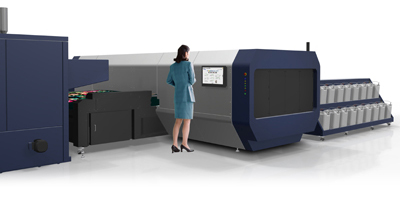

With a maximum print speed of 60 m2 and textile unwinding, printing, drying and textile winding functions all in one, the Nassenger PRO 60 is ideal for small-run production or as proofer for the Nassenger PRO 1000.