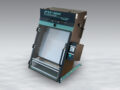

Mimaki announced a brand-new textile printer, the TX300P-1800B (Belt). This 1.8-meter-wide printer is specifically designed to address the need in the textiles and apparel industries for cost-effective short run printing of textiles for products or samples. Its unique design makes it suitable for printing on a wide variety of fabrics, including bulky textured materials, as well as sheer fabric and stretchy materials. It also reduces the space required for on-demand textile printing by eliminating the need of steaming or washing, which is accomplished by printing with the Mimaki textile pigment inks.

Emerging consumer demand

“As consumers increasingly turn to the Internet for their shopping needs, we believe they will want to regularly create custom designs and not rely solely on standard designs available in retail outlets,” says Mike Horsten, general manager marketing of Mimaki EMEA. “In addition to the need to cost-effectively produce samples and small runs, enterprising garment makers will be looking for solutions that will help them meet this emerging consumer demand. And they will not want their fabric types to be as limited as they are with many digital textile printing solutions today.” That’s exactly what the Mimaki Tx300P-1800B belt-type printer was designed for, to meet these needs. Furthermore, the TP400 textile pigment inks allow customers to produce small runs in-house without the need of steaming or washing. Horsten adds, “We believe this new printer is poised to bring significant transformation to the textile and apparel industry with its speed, quality and flexibility at an affordable price point. We are looking forward to showing the first machines at Viscom Italia in the next few days at the Bompan booth.”

Five ink types increase flexibility

In order to accommodate this wide range of requirements, Mimaki offers five different ink types. The first are sublimation dye inks, which work perfectly with polyester-based textiles, either direct to fabric or to a sublimation paper for transfer to the fabric by a heat press. They feature a deep and powerful black, durability and a broad colour gamut. The second sort are dispersion dye inks, which deliver high lightfastness and outstanding build-up on polyester and micro-polyester for sportswear, curtains, outdoor textiles, home textiles and the auto industry. Probably the most flexible are the Mimaki textile pigment inks. There is no need for steaming or washing, which reduces time, costs and potential water pollution. However, a binder or primer is recommended to achieve the quality that both manufacturers and consumers demand. For printing on more natural fibres, like cotton, silk and wool, the reactive dye inks are suitable. The results are sharp images and rich, deep colours. Last, but not least, there are the acid dye inks, which require pre-/post-treatment of the fabric, producing bright, deep colours, and having good light- and wet-fastness, as well.

Technical details of the Mimaki Tx300P-1800B printer:

– Offers entry-level textile printing;- Prints at speeds of up to 50 square meters per hour, and can achieve print resolutions up to 1440 dpi;

– Enables high quality printing on thick, woven or raised fibre textiles, thanks to the high head gap options that prevent head strikes;

– Is equipped with a ‘crumple-free roller’ and ‘paste roller’ on the belt conveyance system, resulting in beautiful, stable results;

– Uses a nozzle control unit to automatically detect and recover clogged nozzles;

– Uses two-litre ink packs to support continuous printing with reduced operating costs; and

– Uses a waveform control technique to jet each ink according to its own specific gravity and viscosity for precise placement of ink droplets onto the fabric.